The incompatibility of growing production and consumption with ecological and resource barriers show that out economic model needs a re-think. Greening the industry also means transforming the consciousness of all players and ‘joining the dots’ between the industrial and natural ecosystems. There are new technologies and circular economy practices that can help us do this, but first we need to change our lifestyles and perceptions of what are ‘good’ goals to have when taking the environment into consideration.

Making all ecosystem players aware of how to use their potential to become ‘positive ecosystem engineers’ is key to find creative ecological solutions, which can transform industrial activities from environmentally harmful to nature-friendly endeavors.

Industrial Symbiosis (IS) as example of how industrial players have been ‘closing the loops’ in production processes

Industrial symbiosis is a strategy to orchestrate the development of business cooperation for the adoption of circular economy solutions by bringing companies together in a process of transacting resources, creating “IS synergies”. The main goals of IS are to increase resource efficiency, minimise waste and create new business opportunities, based on the simple idea that the waste or by-products of one company can turn into useful raw materials for another, or that raw materials, water or energy consumption can be optimised by cost-sharing or cooperative projects.

Some of the first long-standing initiatives documented in Europe were started from the bottom up, for instance in Kalundborg, Denmark, where local companies were driven by the discovery that they can create more business opportunities by re-using by-products from neighbouring businesses in their own industrial processes. The companies organised themselves independently, growing a genuine ecosystem of IS synergies. However, aside from Kalundborg, there is little evidence of the spread of such bottom-up IS initiatives at such a scale. Aside from eco-industrial parks, IS has spread in the EU through top-down support programmes based on the example of the UK National Industrial Symbiosis Programme (NISP).

If IS is such a good idea, why is it not happening at scale?

If we were able to find a new use for the mountains of waste that are currently landfilled, we could achieve not less than €72.7 billion in possible savings across the EU.1 Thus, considering merely the amount of waste that is produced as a whole in Europe in specific sectors, we see that there are massive opportunities for IS initiatives. Recycling of critical raw materials, batteries, solar panels and other renewable technologies is one of the sectors with large market potential.

However, the added value that IS initiatives bring to industries is potentially hard to demonstrate within the current fiscal and regulatory frameworks and economic context. Landfill bans and taxes act as a catalyst for “picking low-hanging fruits”, ie. in diverting waste from landfill or increasing waste re-use in sectors using animal, food, or vegetable waste. However, simply increasing landfill taxes does not produce the expected effects in more complex IS projects, which develop better forms of valorising waste or by-products. More conditions need to be in place for companies to enter into higher added value IS synergies. Significant regulatory and systemic barriers that hamper IS from being spread include for instance the need to clarify standards for “by-products” at EU level, the need for guidance for implementing the End of Waste Criteria or improve eco-design requirements for easier dismantling, reuse or recycling. These issues make it hard for some materials to be re-introduced in the economic cycle for the moment.

The traditional business case for IS initiatives is hampered by a number of further factors. Aside from the policy and regulatory difficulties, companies experience technological barriers to incorporating by-products into industrial processes, which is why often an R&D or technological development cooperation needs to be put in place. A deeper knowledge of assessing particular material flows in industries, or of identifying different uses of by-products or materials across industries are also key for implementing IS, as are the improvement of technological capability and awareness of technological advancements. The building of a user-friendly platform for knowledge sharing at EU level could help in sharing experiences and offering peer support to IS facilitators.

Developing a better evidence base for IS is another crucial step for the future. There is a consistent lack of proper monitoring and evaluation of most IS facilitation initiatives, with the notable exception of NISP and NISP-like EU-funded short-term programmes, as well as larger-scale initiatives such as the Finnish IS System. : These are some very positive examples, but in most cases, it is not clear what is the scale of IS initiatives’ environmental impact.

Cooperation across sectors and organisational boundaries is crucial in IS

A positive side-effect of Industrial Symbiosis is the opening up of innovation channels for the companies scouting for IS synergies. IS often requires changing companies’ production processes or the recognition of opportunities for introducing new products on the market based on underutilised resources.

IS facilitators have been increasingly incorporating in their service offering the support to innovation processes in companies with potential for IS, or support to finding financing solutions. This can be done through e.g. involving clusters, open innovation brokerages or transferring knowledge from R&D processes, all with the purpose to develop IS synergies of higher value added for the environment and companies. For example, Catalisti cluster in Flanders, Belgium, uses open innovation processes as a means to develop public-private-academic cooperations on sustainable production processes. Many IS synergies created by NISP UK needed an initial R&D phase before the IS transactions could be put in practice.

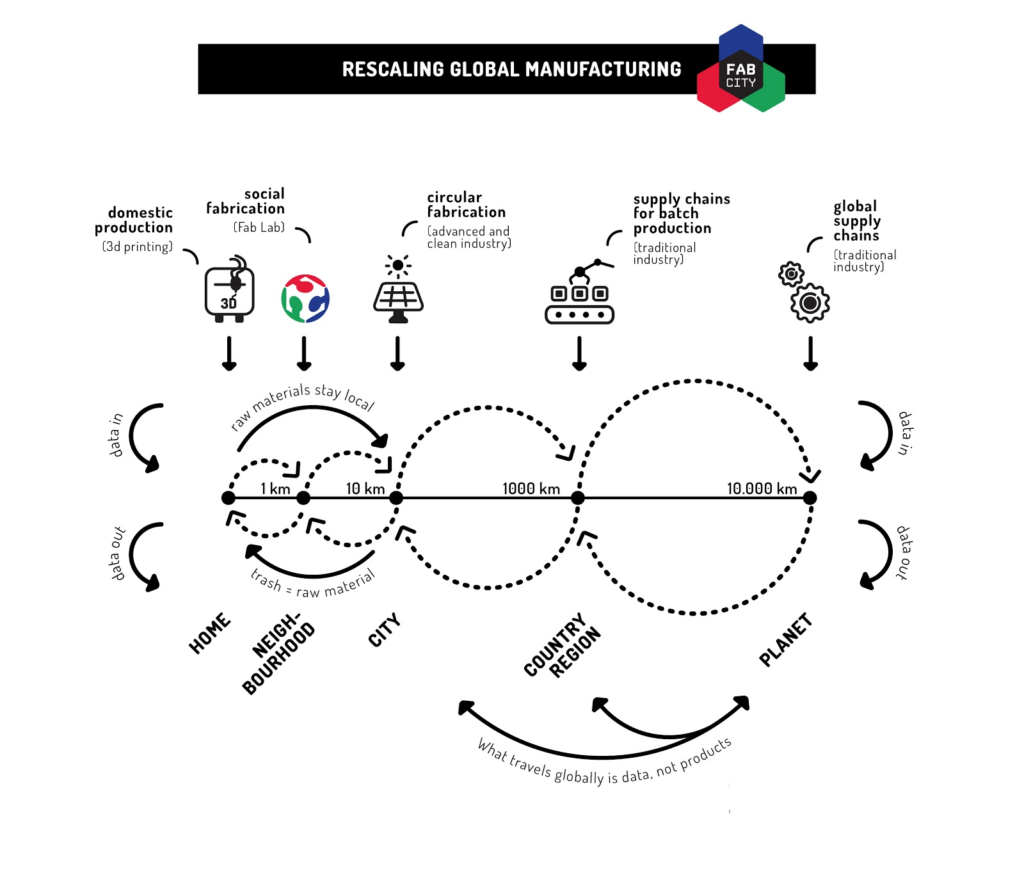

The rising movements of decentralised digital fabrication or 3D-printing, open-source collaborations and democratized production through the maker and FabLab movements have an important potential to enhance opportunities of cross-sector cooperation. A principle the FabLab and maker movements have in common with natural ecosystems is their ability to share knowledge and cooperate freely, beyond the walls of an individual business or industry, since they see knowledge as a “commons”, or public good. There are numerous examples of how low-cost fabrication designs, software or apps are now shared and freely available on websites and Wikis to be used by makers around the world (e.g. Open Source Ecology, Farm Hack, or Open Building Institutes etc.).

Going a step further and imagining urban systems working in symbiosis, the Fab City Foundation, a network of FabLabs, operates with the mission to “produce and consume locally, while sharing knowledge globally”. Re-using, re-purposing or re-designing production processes or products to fit ecological needs within the constraints of lower costs and more localised production could also be facilitated through such a network.

Solutions may thus come from unexpected sources, which are not necessarily the usual suspects in industrial symbiosis. However, given the need to accelerate the process of making this type of solutions a common practice, sharing knowledge, building capacity and removing the regulatory barriers are key steps.

1 – Technopolis Group, UCL et al, 2018: Cooperation fostering Industrial Symbiosis: market potential, good practice and policy actions, a study for European Commission, DG GROW.